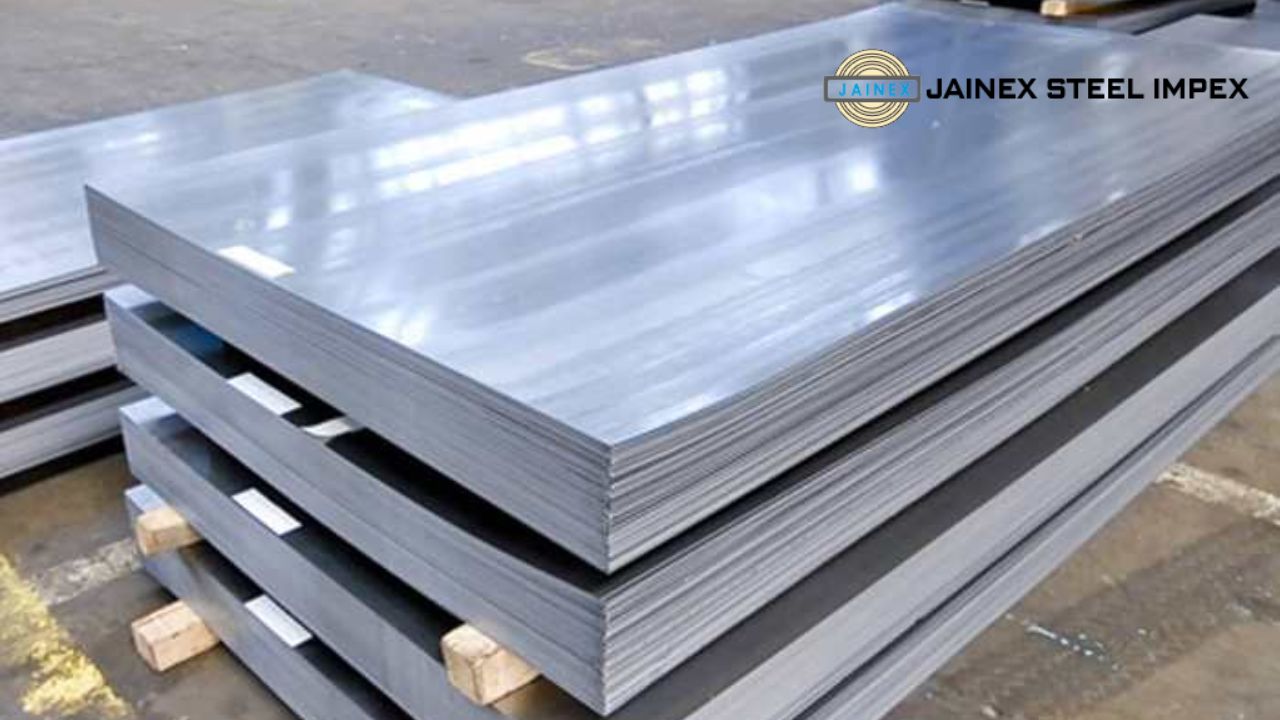

The choice of materials impacts how safely machines work, how long structures last, as well as reliable final products look. A poor material choice can raise costs, slow work, and cause early failure. This is why many industries rely on stainless steel sheets for daily operations. It provides strength, corrosion resistance, and consistent performance under stress. A reliable stainless steel sheet supplier can assist in ensuring that performance is consistent across batches and projects. Stainless steel sheets are used in various applications, such as hygienic food processing and heavy industrial equipment. This blog discusses why stainless steel sheets are popular, where they are used, and the advantages they provide in manufacturing, building, and processing situations.

Key Properties of Stainless Steel Sheets

Stainless steel is not just one material; it is a specialised alloy designed to perform under pressure. Its physical properties make it a top choice for engineers and builders across the globe.

- Corrosion Resistance

The unique feature of this metal is its capacity to resist corrosion. It contains chromium, which creates a thin coating that safeguards the surface from moisture, and air. This indicates that the metal remains the same despite exposure to chemicals or salt.

- Heat Resistance

These sheets do not warp or melt easily when temperatures rise. They maintain their structural integrity in high-heat settings like ovens or industrial engines. This thermal stability keeps machines running safely for longer periods.

- Strength and Durability

These sheets are very tough, even though they are easy to shape. More than most metals, they can withstand heavy loads, and don’t dent or scratch easily. Because of this strength, buildings will last for decades.

- Aesthetic Appeal

The shiny, bright finish on a stainless steel sheet makes it look clean and polished. It works excellently in current designs, as it reflects light and does not require any extra paint. It is easy to maintain the smooth, shiny surface.

- Low Maintenance

Cleaning this material is easy and does not require the use of harsh chemicals. The non-porous surface prevents dirt, and bacteria from concealing themselves inside crevices. This makes it a preferred choice for locations that require impeccable cleanliness.

Industrial Applications of Stainless Steel Sheets

Stainless steel is used across almost every industry due to its remarkable versatility. Its adaptability enables seamless transition from robust construction to delicate medical instruments without interruption.

- Automotive

In the car industry, these sheets are used for body panels and exhaust systems. They protect the vehicle from road salt and high exhaust heat. This helps cars last longer and keeps them looking good on the road.

- Construction

Architects use stainless steel for roofing and wall cladding. It provides a modern look while supporting the weight of large buildings. Since it does not rust, the exterior of a building stays safe and attractive for years.

- Food & Beverage

Cleanliness is everything in food production. Manufacturers use these sheets for storage tanks and kitchen counters because they don’t react with food. It is the safest material for keeping our meals free from contamination.

- Medical & Pharmaceutical

Hospitals rely on stainless steel for surgical tools and lab equipment. It is easy to clean, which reduces the spread of germs. The metal is also durable enough to withstand the continuous cleaning required in medical environments.

- Energy, Oil and Gas

In the energy sector, pipes and machinery can withstand extreme conditions. Stainless steel sheets are used to build heat exchangers and offshore platforms.

Advantages of Using Stainless Steel Sheets

Beyond basic performance, stainless steel sheets offer long-term value. These benefits explain their wide industrial use.

- Long Lifespan

This material is built to last. While other metals might crumble or rust away, stainless steel stays functional for a lifetime. This material reduces the cost of replacing it every few years.

- Low Maintenance Costs

The surface stays functional with simple cleaning. No special coatings or treatments are needed. Maintenance budgets stay controlled.

- Eco-Friendly and Recyclable

Stainless steel is beneficial for the environment. It can be recycled 100%, which means that old sheets may be melted down, and used to manufacture new ones. This cuts down on waste and helps keep natural resources safe.

- Cost-Effective Over Time

Initial costs may be higher than basic steel. Over time, fewer replacements lower total expenses. This makes stainless steel a smart long-term choice.

Choosing the Right Stainless Steel Sheet Supplier

The performance of the metal depends heavily on where it comes from. Picking a trusted stainless steel sheet supplier is just as important as the material itself.

- Quality Certifications

Always check for standards like ISO or ASTM certifications. These labels prove that the metal has been tested for strength and chemical balance. A good supplier will be happy to show you their quality reports.

- Wide Range of Options

The project may require a specified thickness or grade of steel. A professional stainless steel sheet supplier maintains a large inventory to meet various requirements.

- Customization Options

Sometimes standard sizes won’t work for a specific design. Look for a partner who offers cutting and finishing services, which saves time.

- Timely Delivery

Industrial projects operate under stringent timelines. It is essential to have a supplier who is capable of delivering the product on time and without excuses for delays. Reliable shipping and transparent communication are signs of a professional business associate.

Conclusion

In modern industries, stainless steel sheets are quite important. They help keep things safe, strong and reliable for a long time in various circumstances. Their performance is steady under pressure, whether it’s in food plants or energy systems. Their resistance to corrosion, heat, and wear reduces downtime and maintenance costs. Selecting the right grade and working with a reputable stainless steel sheet supplier provides constant quality, and better results. Investing in stainless steel sheets provides industries with long-term durability, efficiency, and predictable performance.